LossLess Group

LossLess Group

Technology

Data management innovation

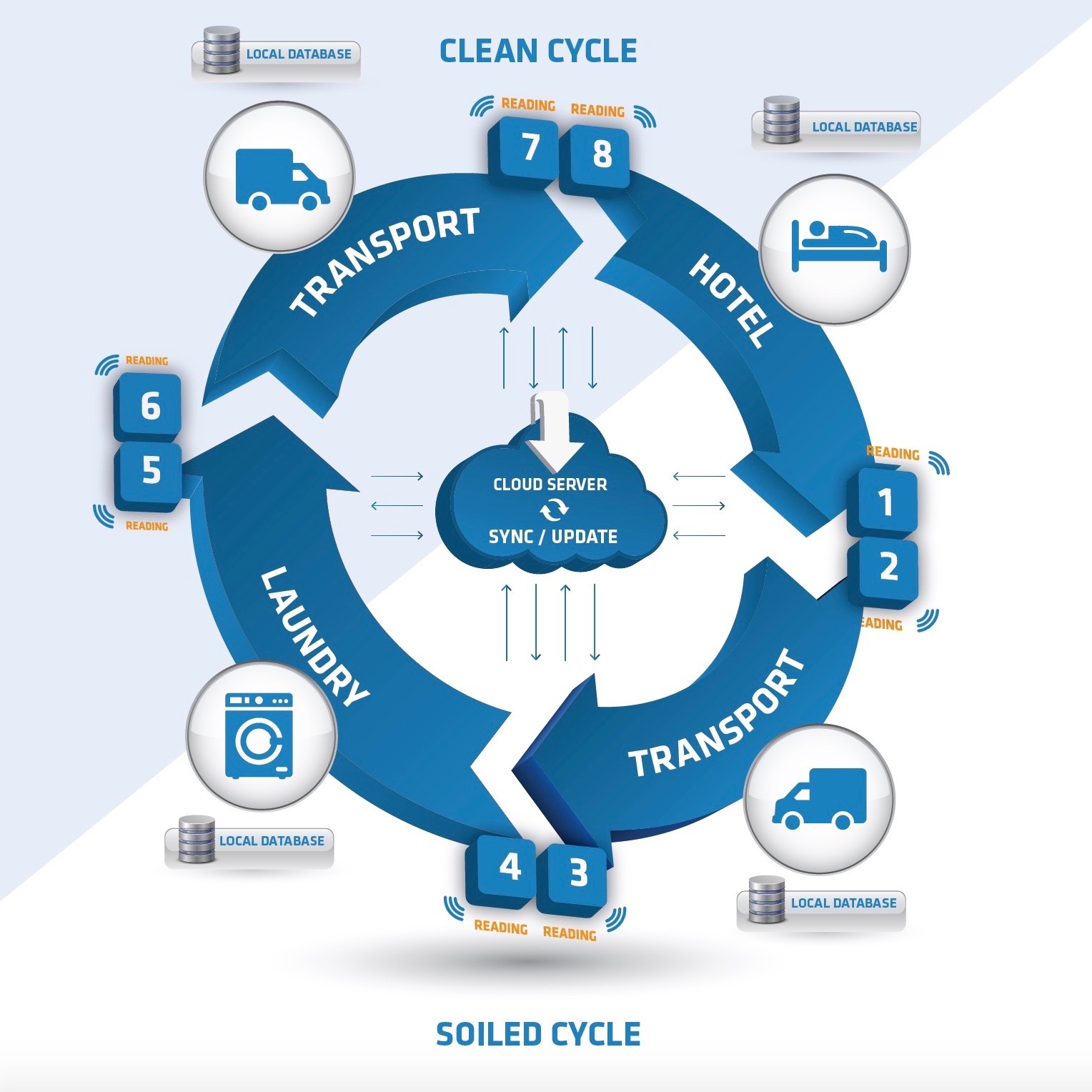

The common denominator of industrial textiles is that laundries pick up soiled linen, wash, and return it clean in a continuous logistic cycle. Our tracking process runs in parallel, recording the transfer of goods each time these change hands, and responsibility is transferred to the next party.

The tracking process interferes in no way with the logistic cycle, which remains unchanged.

The efficiency and quality of tracking of tagged items is measured by the completeness of data capture at each of the reading stations. Poor read performance of UHF RFID enabled items is one of the main reasons for past failures.

The most impactful improvement of the tracking process is our invention of an aggregation algorithm, which delivers unprecedented reading accuracy.

The industry norm has been to use ‘brute-force’ to maximize results, by relying on increasingly more powerful and sophisticated readers with multiple bigger antennas, in an attempt to achieve maximum accuracy in one single reading.

However, results did not improve sufficiently, as physical factors such as humidity, density and position of tags, the material of a laundry container, etc. interfere with the electromagnetic field. This makes 100% accuracy in one reading at best improbable, irrespective of the power of the reader used.

Instead of relying on hardware-based ‘brute-force’, our tracking process comprises multiple readings. Accepting regular incompleteness of readings, our software uses aggregation algorithms to create full accuracy.

At the time of its development, aggregation in textile tracking was so innovative that we were awarded a patent for its invention.

Read more

You may also like...

Enabling transformation

The challenging time of Covid lockdown has impacted on people in many ways, some withdrawing into hermit like isolation, some going a bit crazy to entertain themselves, and some have used the opportunity to hit the ‘pause button’ on their […]

Read moreThe future of textile management

RFID tracking has been long coming as the inevitable future of textiles management. However, it never did, and it’s now at least 10 years overdue. Reasons given to explain this failure are cost, lack of accuracy and the absence of […]

Read moreEPCglobal and IoT

Many people have accused The Internet of Things of being a solution looking for a problem. However, at its inception, it was a solution for a very real problem. The US retail industry was running out of barcode combinations, and […]

Read more