LossLess Group

LossLess Group

Every revolution in history has been preceded by a great crisis, lighted by a spark and spread by a team of believers. At LossLess Group we believe that we are at the inception of the connected textiles revolution, and everything around us at the moment confirms this belief.

The great crisis that precedes this revolution is, of course, Covid-19. As of today, we still don’t know how long it will stay with us, we are all learning as we go, but it is affecting every aspect of our lives in unprecedented ways.

We believe that a consequence of this crisis will be a much higher acceptance of change, especially of those aspects of the previous normal that were not so good to begin with.

All stakeholders in the textile management industry have been equally affected. The lock down meant travellers stayed at home, hotels experienced a dramatic drop in occupancy, and laundries and textile manufacturers lost their source of business.

The industry came to a halt, and many in it have been left fighting for survival. Latest estimates indicate that up to 25% of all jobs in hospitality may be lost by the end of the year.

The spark that will help ignite the fire is our RFID technology, and the alternative management strategies it enables. Through its implementation hotels improve their GOP by over 5%, whilst finally gaining control of their textiles and laundry operations, and saving cash while doing so.

It’s so much more than just technology, and so revolutionary, that we had to give it a new name: TaaS, Textiles as a Service.

We are looking for a few select people who dare to think differently, to join us and contribute to transforming the way textiles are managed everywhere. We believe this is the opportunity of a lifetime, in a time of global change.

If you think you have what it takes and are ready to join the revolution, click below to see our career opportunities and apply to be part of the action.

https://losslessgroup.com/en/careers/

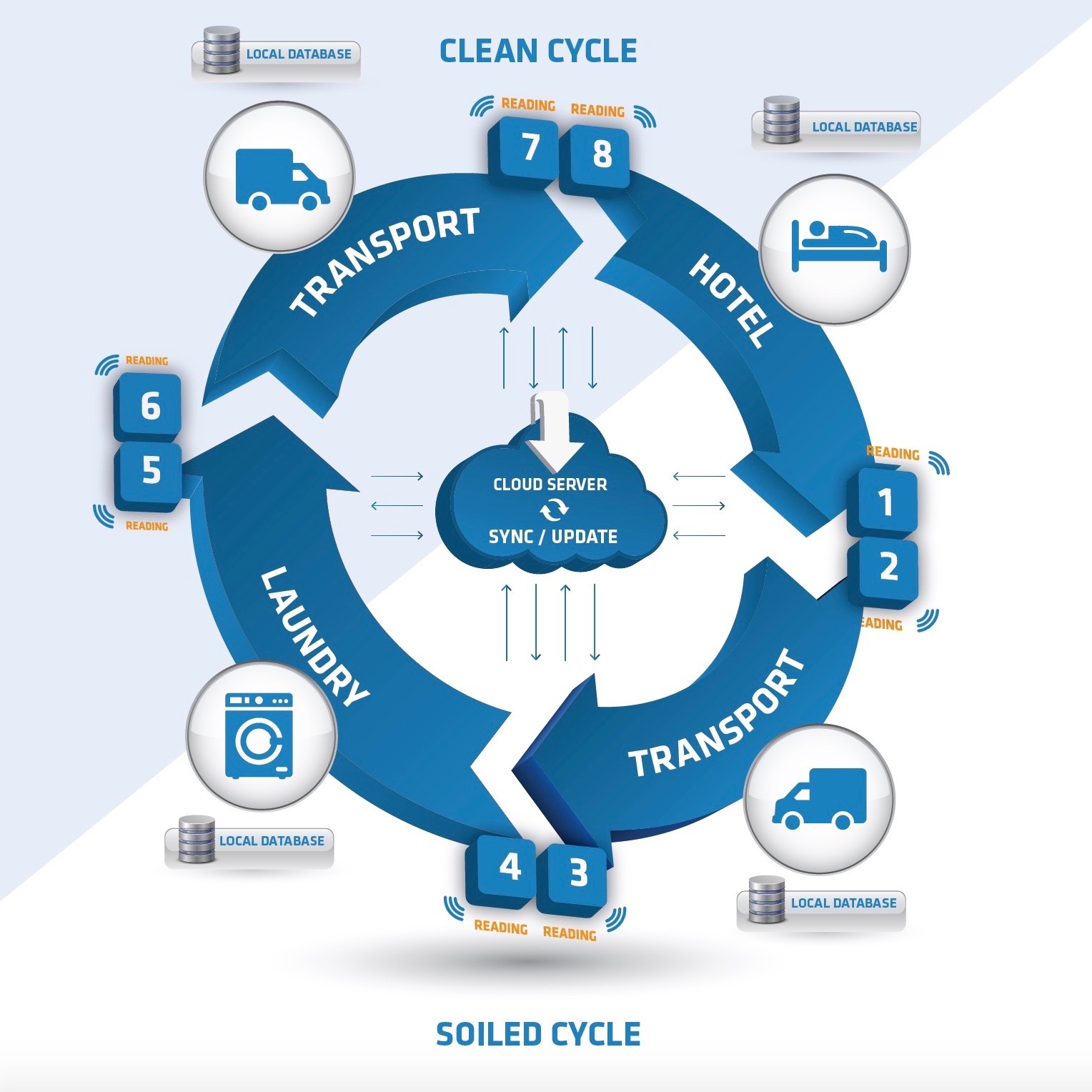

The common denominator of industrial textiles is that laundries pick up soiled linen, wash, and return it clean in a continuous logistic cycle. Our tracking process runs in parallel, recording the transfer of goods each time these change hands, and responsibility is transferred to the next party.

The tracking process interferes in no way with the logistic cycle, which remains unchanged.

The efficiency and quality of tracking of tagged items is measured by the completeness of data capture at each of the reading stations. Poor read performance of UHF RFID enabled items is one of the main reasons for past failures.

The most impactful improvement of the tracking process is our invention of an aggregation algorithm, which delivers unprecedented reading accuracy.

The industry norm has been to use ‘brute-force’ to maximize results, by relying on increasingly more powerful and sophisticated readers with multiple bigger antennas, in an attempt to achieve maximum accuracy in one single reading.

However, results did not improve sufficiently, as physical factors such as humidity, density and position of tags, the material of a laundry container, etc. interfere with the electromagnetic field. This makes 100% accuracy in one reading at best improbable, irrespective of the power of the reader used.

Instead of relying on hardware-based ‘brute-force’, our tracking process comprises multiple readings. Accepting regular incompleteness of readings, our software uses aggregation algorithms to create full accuracy.

At the time of its development, aggregation in textile tracking was so innovative that we were awarded a patent for its invention.

https://losslessgroup.com/en/uhf-rfid/

The challenging time of Covid lockdown has impacted on people in many ways, some withdrawing into hermit like isolation, some going a bit crazy to entertain themselves, and some have used the opportunity to hit the ‘pause button’ on their task oriented working life, to reflect and take stock on some strategic issues that we often do not have the time to contemplate.

Certainly, at LossLess Group we fall into the latter category. As a relatively young business we have been flat out doing today’s important things and not always allowing our strategy and purpose to catch up. The Covid ‘pause’ has allowed us to reflect on what we are trying to achieve, and how we are going about it.

We have also been able to document in detail, and after careful consideration, our strategy and business plan. This has led to our development of a new website, social media presence and a clear sense where we a travelling.

Perhaps the toughest challenge has been to define what we actually do. In the past, businesses have had a simple definition, as retail, manufacturing or banking etc. However, today businesses have far more complex definitions, as generally their definition would encompass some element of service, technology, marketing or innovation.

At LossLess Group we provide many activities that combine to make our business unique and compelling. We use highly complex technical RFID equipment to produce data. We have patented algorithms that create valuable information for our customers.

We use the Internet of Things to provide new processes to transform our client’s businesses. We provide a hands-on service to help our clients change the shape of their own operations. We provide leasing solutions to make the transformation cash efficient.

This all makes the challenge of describing our business within conventional terminology as quite mind boggling. Undoubtedly, we provide an asset tracking technology service, using RFID and the Internet of Things to allow businesses to maximize the availability of their key assets. Perhaps we are a ‘transformation enabler’?

Applied to the Hospitality sector, the technology converts commoditized rented hotel linen to valuable tangible assets that can be tracked through their lifecycle journey from room to laundry and back again.

The data generated allows hotels and laundries to reduce the amount of linen in circulation, improving reliability and reducing costs. As an asset, the linen can be financed by leasing it through LossLess Group, resulting in improved cash utilization and increased EBITDA performance.

It all makes perfect sense to us, but if you need more of an explanation about how we transform our client’s businesses, why not get in touch.

RFID tracking has been long coming as the inevitable future of textiles management. However, it never did, and it’s now at least 10 years overdue. Reasons given to explain this failure are cost, lack of accuracy and the absence of tangible benefits.

At LossLess Group, we have systematically worked on fixing each of these concerns. As regards cost, our system basically pays for itself from the savings it generates. Accuracy we achieve through a patented aggregation algorithm built into the system.

Our value propositions generate multiple benefits, not only measured in operational and financial terms.

Our services also address health and safety concerns, and contribute to environmental sustainability.

Connecting textiles turns them into assets with a residual value. This attribute opens up lease, a transaction option not available to date. Lease marries the economics of owning assets with the cash flow benefits of renting.

Traceability provides information about the price of textiles, items in circulation, number of washes, and losses. This functionality sheds light on the composition of the all-inclusive pay-per-wash tariff, generally used in the industry.

Often, hotels and hospitals choose a rental service because they find it difficult to control the lifecycle of their textiles. This choice is made despite a lack of understanding the real economics of that service.

From a financial perspective, visibility gained from traceability begs the question if rental of assets that are used on a daily basis should still be the preferred option.

This extension of transaction models is a natural consequence of the inevitable evolution of technology. As such, it should not be perceived as offensive, but as call for change. Connected textiles is a new industry that opens up a plethora of opportunities.

Everybody has a role to play, and an opportunity to benefit from these opportunities. Contact us if you want to know more.

https://losslessgroup.com/en/uhf-rfid/

Homer Simpson famously said, there are only three kinds of people in the world: Those who can count and those who can’t. Whilst I tend to agree with Homer, in this occasion I do not, as I think there are only two types of people in this world: those who see the glass half full, and those who see it half empty. The fascinating matter of the fact is that there is no glass, so when you see half full, you always do, regardless.

Covid-19 has changed our world in unprecedented ways, but not all bad. Its fast forwarded adoption of new habits that we’ve discovered makes a lot of sense.

We have relied on technology to do more with less, we have learnt to meet without travelling and to work without an office. We have rediscovered that gratis is great, that it’s ok if the backdrop is your bedroom, or to hear kids in the background, and that it’s fine to wander around the house to find a working spot. And if the dog barks, it barks. Because dogs bark.

The post-COVID-19 world has embraced change and that is great news for entrepreneurs, because they invent the future, and that will be easier now.

Glass half full

Many people have accused The Internet of Things of being a solution looking for a problem. However, at its inception, it was a solution for a very real problem. The US retail industry was running out of barcode combinations, and approached MIT to develop a different method to represent data.

The solution MIT came up with was EPCglobal, the global standard for UHF-RFID identification. Not surprisingly, its potential went far beyond and above its original scope of replacing the primitive barcode. It created options nobody had contemplated yet, like connecting things.

When a technology is ahead of its time, the world takes a while to catch up. Nearly 20 years have passed since EPCglobal was founded, and many people still have doubts about the Internet of Things. It has proved to be difficulty to marry usefulness with an effective monetization model. As a result, we have incorporated only a surprisingly small number of connected things in our lives. Instead of the Internet of Everything, it looks more like the Internet of Nothing.

At LossLess Group, we believe we have found a problem that has been desperately looking for a solution. We have adapted the EPCglobal technology to manage industrial textiles, as used in hospitality and healthcare. TaaS, Textiles as a Service, delivers unprecedented control throughout the lifecycle of textiles. It offers operational and financial savings, and contributes to health & safety, and environmental sustainability.

TaaS benefits all parties involved in the textile trade, from hospitals to hotels, laundries and textile manufactures. Long live the Internet of Textiles.

The prerequisite for any RFID-enabled linen tracking system is that assets are equipped with an UHF RFID tag. There are many tag suppliers, using different combinations of components, but the basic construction and composition is roughly the same.

At the core of a tag is a lentil, an enclosure made of epoxy resin, that contains the UHF RFID chip and a primary antenna, which is used for Near Field Communication (NFC). This is a way for objects to communicate over a short distance, for instance when you pay for groceries using the chip on your credit card. The encapsulation of the chip is done to protect it from exposure to harsh laundry environments.

The next component is a secondary antenna, often a wire or metallic thread, sewn into the carrier in a specific shape. This antenna enables communication over greater distances. Finally, there’s a carrier, mostly a textile material composed of polyester, or a combination of polyester and cotton. The durability of this carrier determines the lifetime of the tag.

Besides the quality of a UHF RFID tag, there is also the cost to consider. Prices have decreased from around one Euro in 2005 to under 30 cents per tag. This makes it more attractive to virtualize textile assets on a larger scale.

However, what is often forgotten is the additional cost of attaching the tag to the textile item in order to make it ‘connected’, i.e. able to communicate with other connected objects through the Internet of Things. The preferred time for tag integration is during the production process, rather than retrofitting existing linen. The cost of manual attachment can be up to 30 cents, an added expense that should be eliminated, or at least reduced to a minimum.

At LossLess Group, together with our partners, we have developed UHF RFID tags on a roll that, when used on a labeling machine, enable automatic integration during the production process at no additional cost. This has been successfully tested at Standard Textile, one of the large manufacturers of hospitality and healthcare linen.

Featured image from Pexels by Engin Akyurt

Donec purus risus, feugiat id rutrum id, volutpat a augue. Ut dui ipsum, laoreet ac feugiat sollicitudin, volutpat a urna. Ut mollis elit erat, nec egestas ex accumsan sit amet. Phasellus consectetur nibh eget pretium feugiat. Quisque dapibus nisi a sem ullamcorper congue. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia curae; Phasellus nec ornare ante.

Fusce enim nibh, auctor in dui id, faucibus luctus turpis. Etiam scelerisque tortor lorem, quis accumsan nisl facilisis at. Donec lobortis sapien vel orci malesuada aliquet. Quisque vitae magna eu sapien cursus ultricies non rhoncus dolor. Nulla vel sodales nunc. Donec malesuada, mi a hendrerit tempor, tortor urna rhoncus quam, et viverra elit velit sed ligula. Donec quis nunc dapibus, venenatis ex ac, varius augue. Nulla semper suscipit vehicula. Donec velit orci, tempor eget laoreet sed, ullamcorper ac ex. Fusce quis dignissim risus. Nunc sit amet rutrum ipsum. Fusce eu nunc ipsum. Nullam ac metus ut magna blandit vulputate. Ut commodo pellentesque dolor, at consectetur purus lobortis a. Integer molestie tellus sit amet nulla mollis, non rutrum enim mattis.

Donec scelerisque est nulla, pulvinar dapibus ligula viverra eget. Nunc elementum volutpat nisl, quis tincidunt urna ullamcorper a. Vestibulum mauris est, sagittis fermentum leo a, posuere aliquet risus. Donec a leo sit amet nulla imperdiet feugiat et ac massa. Fusce efficitur congue porttitor. Ut molestie nulla a risus ultricies, ut pulvinar risus mollis. Mauris ut scelerisque odio. Aenean fermentum placerat diam, volutpat porttitor magna iaculis a. Sed ultrices sem orci, ac auctor justo tincidunt quis. In pulvinar nisi et feugiat hendrerit.

There are countless descriptions of the Internet of Things, and even more fancy infographics to visualize functionalities and benefits. Basically, to explain how it all works. To use one such description: the Internet of Things is a system of interrelated computing devices, mechanical and digital machines, objects, animals or people that are provided with unique identifiers (UIDs), with the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction.

That is quite a mouthful, and I think the most important part of that definition is in the last few words. Eliminating human interference from the process of data transfer is not a bad idea. We tend to impact on communication processes in a way that is not always beneficial to the quality of the outcome. Machines have no personal interest in whatever information is exchanged between them and, let’s be honest, they don’t make as many mistakes as we do. I find it amazing that in our technology-driven society it took so long to come up with such a brilliant idea.

I love the story how Coca Cola back in 1982 modified one of their vending machine at Carnegie Mellon University to automatically report its inventory, and whether newly loaded drinks were cold or not. There is general consensus that vending machine was officially the first Internet-connected appliance. However, most people seem to agree it was Kevin Ashton of Procter & Gamble who actually named it Internet of Things. This was back in 1999, when he was working in supply chain optimization, and attempting to integrate an exciting technology called RFID into that process.

At LossLess Group, we connect textiles by attaching an RFID tag, enabling them to communicate with other RFID-enabled items through the Internet of Things. We have learned very early on not to interfere in that process, which probably explains why our tracking system is so successful.

Hotels, or if we want to use a more confusing term: the lodging industry, use 3 key performance indicators to measure their performance: ADR, RevPAR and Occupancy rate. However, unlike other holy trinities in business, this is really a duality as RevPAR is a product of the other two: RevPAR = ADR x Occupancy rate.

Let’s explain each of these metrics. ADR stands for Average Daily Rate, the price for an occupied room on a given day. Occupancy indicates the percentage of available rooms that are occupied on that day. RevPAR, which stand for Revenue Per Available Room, is calculated by multiplying ADR and Occupancy in the period measured.

Occupancy rate can be influenced, but not controlled by the hotel operator, i.e. they cannot force customers to come to their hotel. They can try to persuade them by implementing dynamic pricing strategies that adapt room rates to current or expected demand.

As a point of reference, during the economic depression between 2008 and 2012, occupancy rates barely moved, but ADR decreased by nearly 25%. There were travelers, but there was no money. A world impacted by COVID, and uncertainty of the state of economy that lies ahead, present an entirely different scenario. Perhaps for the first time ever, there are neither travelers nor money, leaving the hospitality industry gasping for a brand-new way of managing their revenue.

Since this is a health crisis, at LossLess Group we believe that health measures will bring back customers, and we have a solution to assist you realize that goal. Contact us to find out.